Foods & Beverages

We are able to supply and support a variety of different solutions in order to handle food and beverage products.

We are able to supply and support a variety of different solutions in order to handle food and beverage products.

Machines manufactured with FSA, FDF, HSE and FOD certified materials, including stainless steel for all contact parts.

Whether it be heating the media to allow it to be filled as a liquid or handling it within special environments.

Our machines are also designed and manufactured to allow an easy and fast clean down operation to avoid any bug traps. Methods such as electropolishing and crack & crevice welding are all implemented to ensure the best possible machine.

We also offer clean down functions as an automated process, controlled from an HMI Screen.

Our machines can be fully designed with future upgrade in mind!

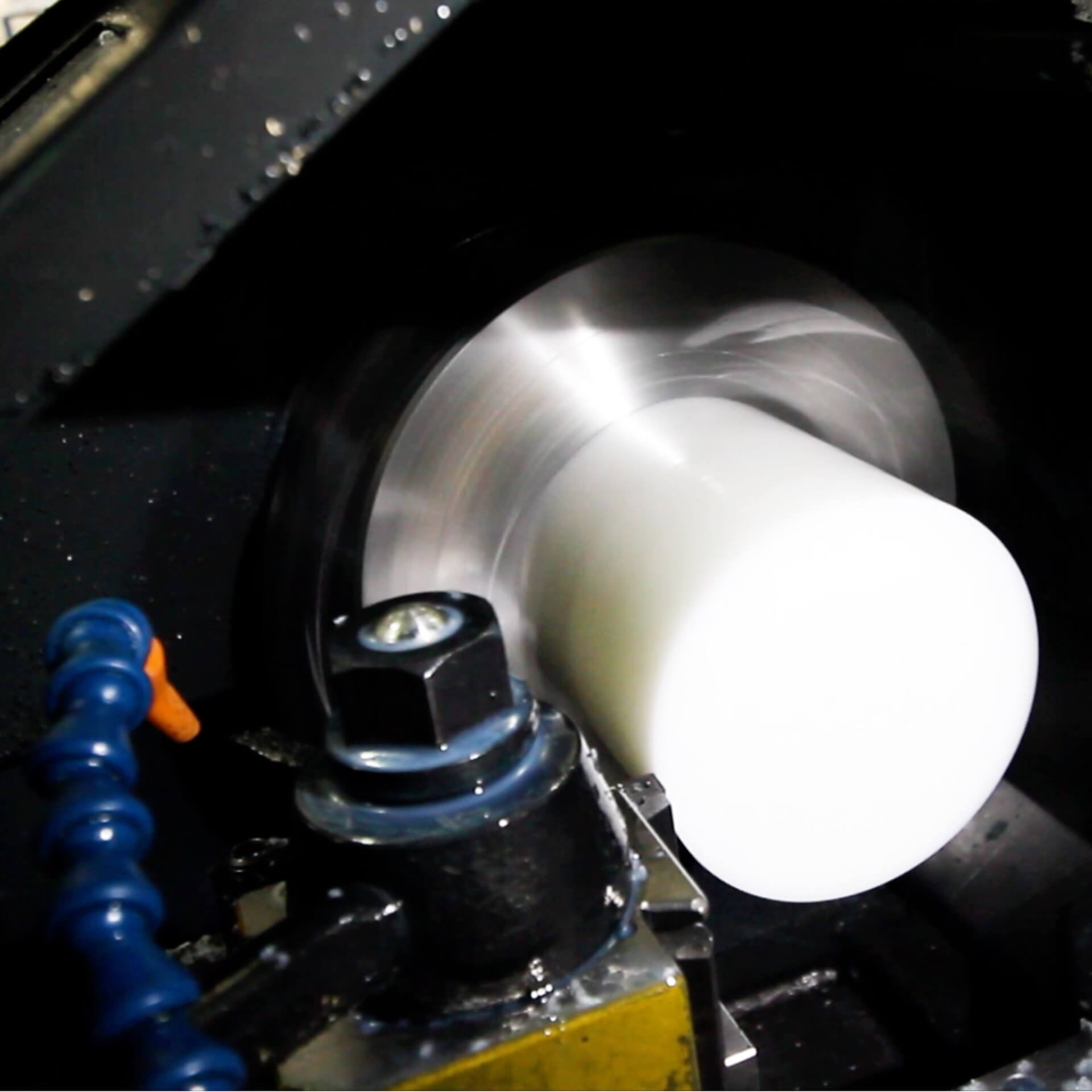

We provide filling machinery systems for every solution.

We also offer a range of capping and lidding machines that may suit your needs!

Whether it be; an MPC-1 pick & place capper, The new MPC-2 Two headed Pick & place Capper, a rotary based capping machine, a sweep on or pick and place lidder or maybe even a crimping solution.

We are also able to handle bottles through the processes of labelling whether it be pre or post fill, offering a Mount Packaging labelling system, capable of either panel labelling, wrap around or just single sided applications.

Our labelling machines are designed to suit your bottle and label for the best possible results.

Mount also offers full de-palletisation systems, from robotic solutions to dennesters, we can design and manufacture a fully bespoke piece of equipment to suit your needs.

We also handle of of line machinery, form intergrated vision systems to check for cap errors or bottle discrepancies.

© 2025 Mount Packaging. All rights reserved.